The Rise of Industry 4.0: SAP’s Role in Smart Manufacturing

Industry 4.0: The Digital Revolution Reshaping Factories

Imagine walking into a factory where machines hum with purpose, algorithms whisper warnings before breakdowns, and supply chains adjust to global disruptions in real time. This is Industry 4.0—a revolution fuelled by IoT, AI, and data analytics. But transforming a traditional factory into a smart one isn’t just about plugging in sensors; it requires robust systems like SAP’s enterprise solutions and partners with deep expertise, such as Exiga Software Services, to bridge vision and execution.

Why Traditional Manufacturing Can’t Keep Up

Most factories still rely on legacy systems plagued by siloed data, delayed decisions, and costly downtime. Consider this: unplanned equipment failures cost manufacturers an estimated $50 billion annually (Deloitte). Industry 4.0 tackles these pain points head-on by:

- Predicting, not Reacting: Machine learning anticipates maintenance needs.

- Breaking Data Silos: Unified systems enable end-to-end visibility.

- Boosting Agility: Real-time adjustments to supply chain disruptions.

But bridging the gap between old and new requires more than just tech—it demands expertise. This is where SAP’s solutions and partners like Exiga, a leader in SAP implementation and optimization, become indispensable.

SAP’s Toolbox for Industry 4.0 Mastery

- SAP S/4HANA: The Brain of Smart Manufacturing

This ERP powerhouse crunches real-time data from production lines, suppliers, and sales teams. A European automaker, for example, slashed inventory costs by 25% after SAP S/4HANA flagged overstocked parts using AI-driven demand forecasts. - SAP Digital Supply Chain: Weathering Disruptions

When a typhoon delayed shipments for a Japanese electronics firm, SAP’s AI rerouted components via alternate suppliers in under 2 hours—saving $4M in potential losses. - SAP Manufacturing Execution: Quality at Scale

A pharmaceutical company reduced batch defects by 30% using SAP ME’s real-time quality alerts, ensuring compliance with FDA standards.

The Future: AI, Digital Twins, and Sustainable Manufacturing

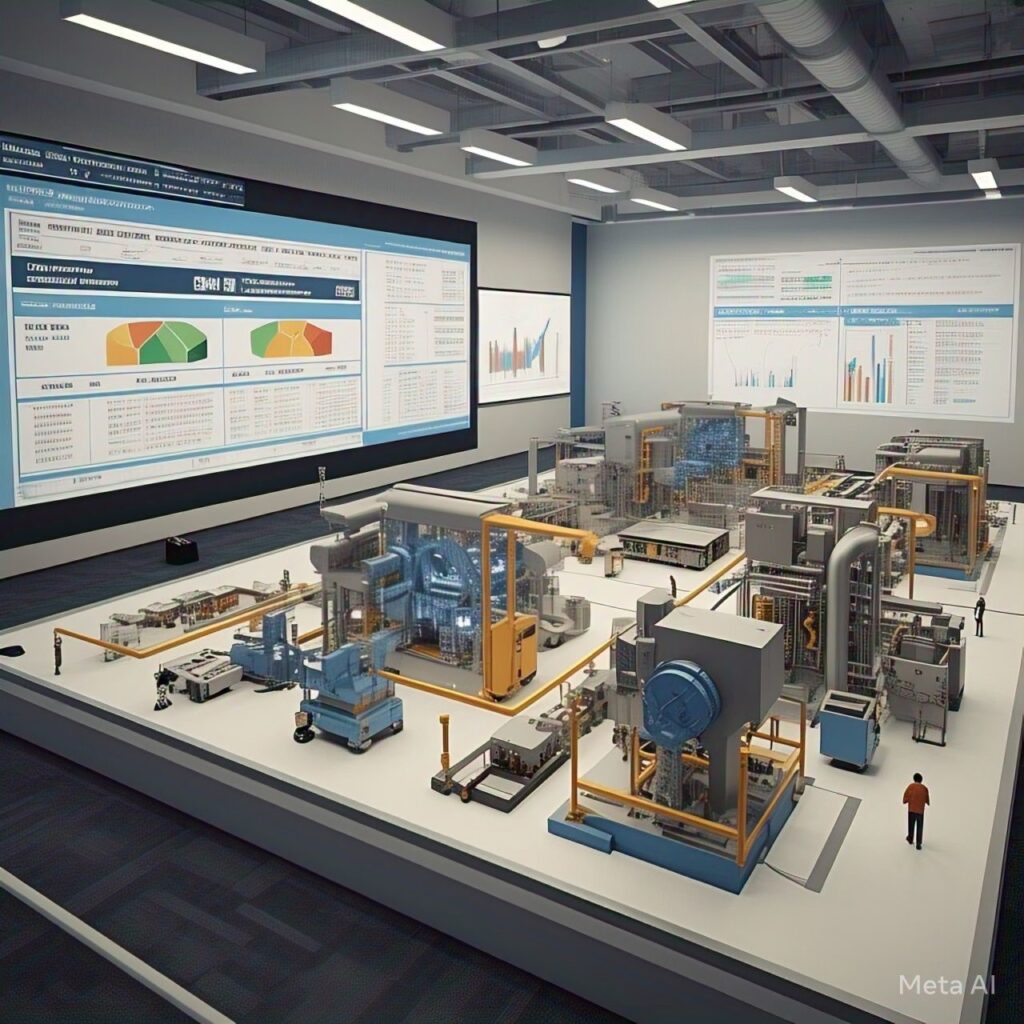

Industry 4.0 is evolving faster than ever. SAP is pioneering:

- AI-Driven Customization: Imagine producing 10,000 uniquely configured products in a single run.

- Digital Twins: Virtual replicas of factories let managers simulate disasters (like cyberattacks) without real-world risks.

- Circular Economy Tools: Track recyclable materials from production to end-of-life, slashing waste.

Conclusion

Industry 4.0 isn’t a solo journey. While SAP provides the tools, success hinges on strategic implementation. That’s where partners like Exiga Software Services shine. With tailored SAP integrations, Exiga helps manufacturers turn data into decisions, reduce costs, and future-proof operations.

Ready to build your smart factory? Explore Exiga’s SAP solutions to start your Industry 4.0 transformation today.